Description

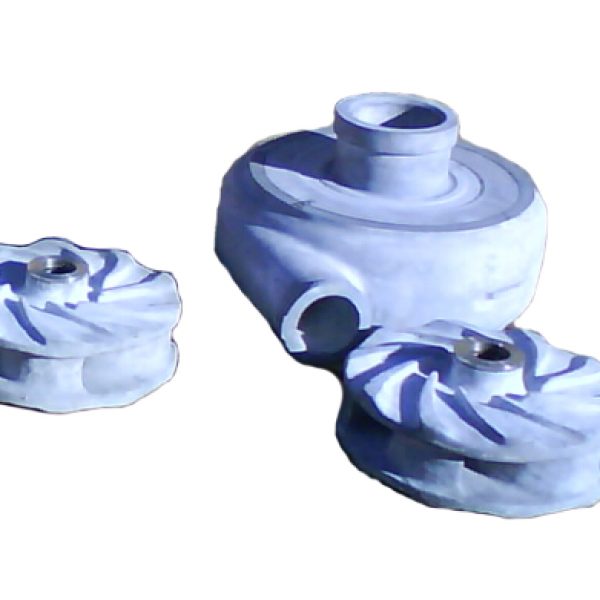

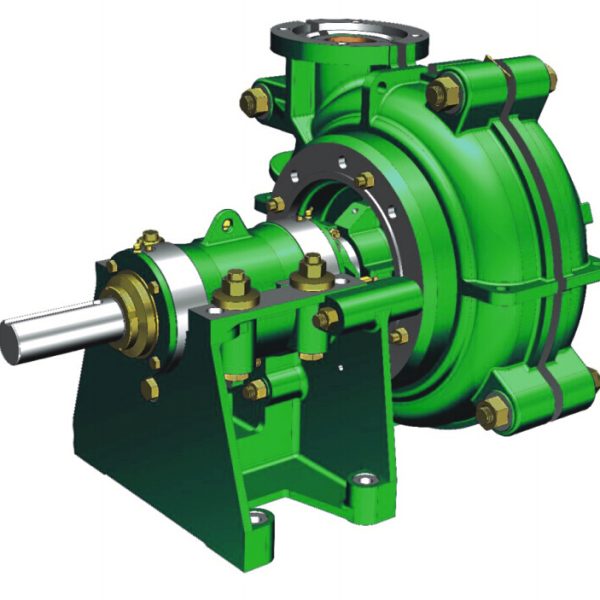

Rubber Slurry Pump Parts

Matec Solutions supply the main Rubber Slurry Pump Parts: Impeller/Cover Plate Liner/Frame Plate Liner/Throatbush/Frame Plate Liner Insert, all of them are genuine replacements for MCR AH ASH Warman Pump Parts, reliable quality enables the steady operation of our customers, high performance of longer wear life help saving the cost. We promise full life cycle guarantee, we take care of our customer and products at any time.

Applications:

Mill Discharge,Cyclone Feeding,Concentration Plant Processing,Tailing Pumping,Chemical Slurry,Quarry

MCR AH ASH Slurry Pump Parts Equivalent Model:

AH:1.5/1B, 2/1.5B, 3/2C, 4/3C, 4/3D, 6/4D, 6/4E, 8/6E, 8/6R,10/8F, 10/8ST, 12/10ST, 14/12ST, 16/14TU, 20/18TU;

L: 50B, 75C, 100D, 150E, 300F, 350S, 400ST, 450ST, 550TU, 650TU;

M: 10/8E, 10/8F, 12/10E, 12/10F;

SPR: 40P, 65Q, 100R, 150S;

MCR: 350, 450, 550, 650 .

Materials Specification:

R08 is an impeller grade rubber, of medium hardness, for use in high wear applications, where erosive and tear resistance is required in fine to medium particle slurries;

R26 is a soft grade material for use in a high wear application. It is a black natural rubber for pump liners in high wear applications;

R55 is a premium grade material for use in a high wear application. It is a black natural rubber, of low hardness for pump liners. Superior physical properties give increased cut resistance to hard, sharp particle slurries. It is ideally suited to mill discharge applications;

S42 is a high strength synthetic rubber with dynamic properties only slightly inferior to natural rubber. It is less affected by temperature than natural rubber, and has excellent weathering and ozone resistence. It also exhibits excellent oil resistance;

Features:

Optimized elastomer liners guarantee extra service life, more uptime with less money;

Wear resistant, corrosion resistant, easy installation and less nosise nor vibration.

Reviews

There are no reviews yet.