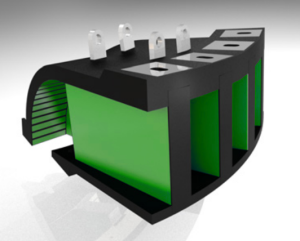

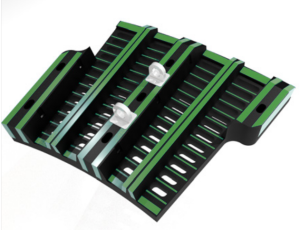

Matec Solutions manufacture Poly-Met Mill linings which combines the most desirable properties of rubber and steel to maximum advantage. This combination allows the use of more wear resistant alloys of iron and steel than can be used in a conventional metallic lining, as the rubber substantially dampens the impact forces and also results in a lower lining weight.

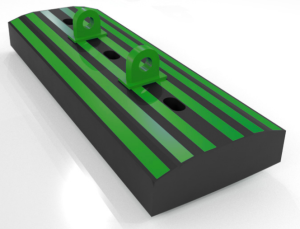

Poly-Met solution including lifter bars, plates and grates. We select alloys and profiles based on your specific application and operating conditions. Different lining materials such as rubber, metallic and Poly-Met can be combined in the same mill to achieve optimal performance.

Application:

AG/SAG/Ball Mill Grinding for mineral processing, cement industry and power plant.

Features:

Poly-Met head linings are designed to use a minimum amount of the metallic component, placed in strategic locations. This results in a light-weight, highly predictable system requiring a minimum number of maintenance stoppages.

Poly-Met shell plates can withstand high impact as they are made of highly resistant alloys in combination with rubber. This results in less cracking and thereby fewer unplanneds stops.

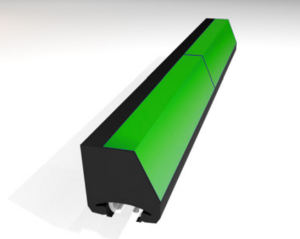

Light-weight components crafted from steel-reinforced rubber are easily installed, and provide long service life. By reducing system mass, it is often possible to increase mill

charge volume without risk of mill structural overload.

Possible to execute a complete lining renewal in a single maintenance stop. Combine this with efficiency of operation and long service life, and you have a proven solution to improve your bottom line.

The strong yet flexible materials used in Poly-Met and rubber grates make it possible to reduce or totally eliminate pegging problems and maintain aperture sizing, which stabilizes your product size distribution and circuit capacity.