Description

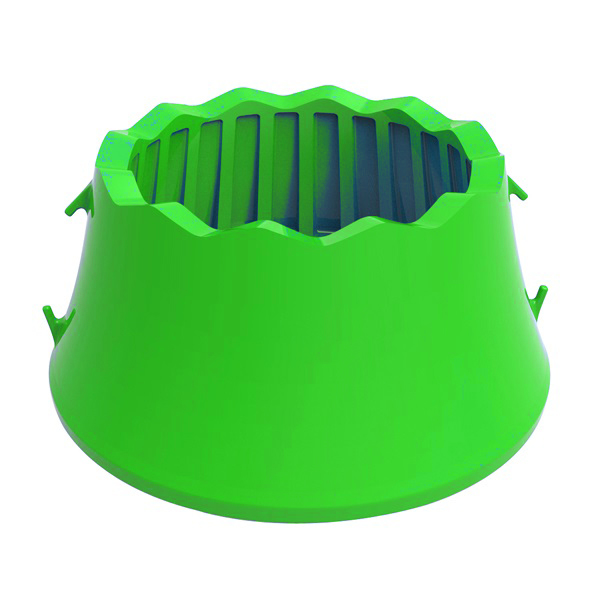

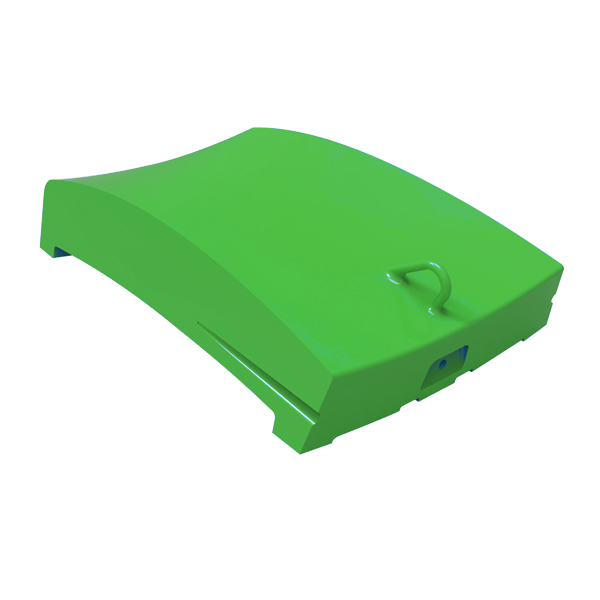

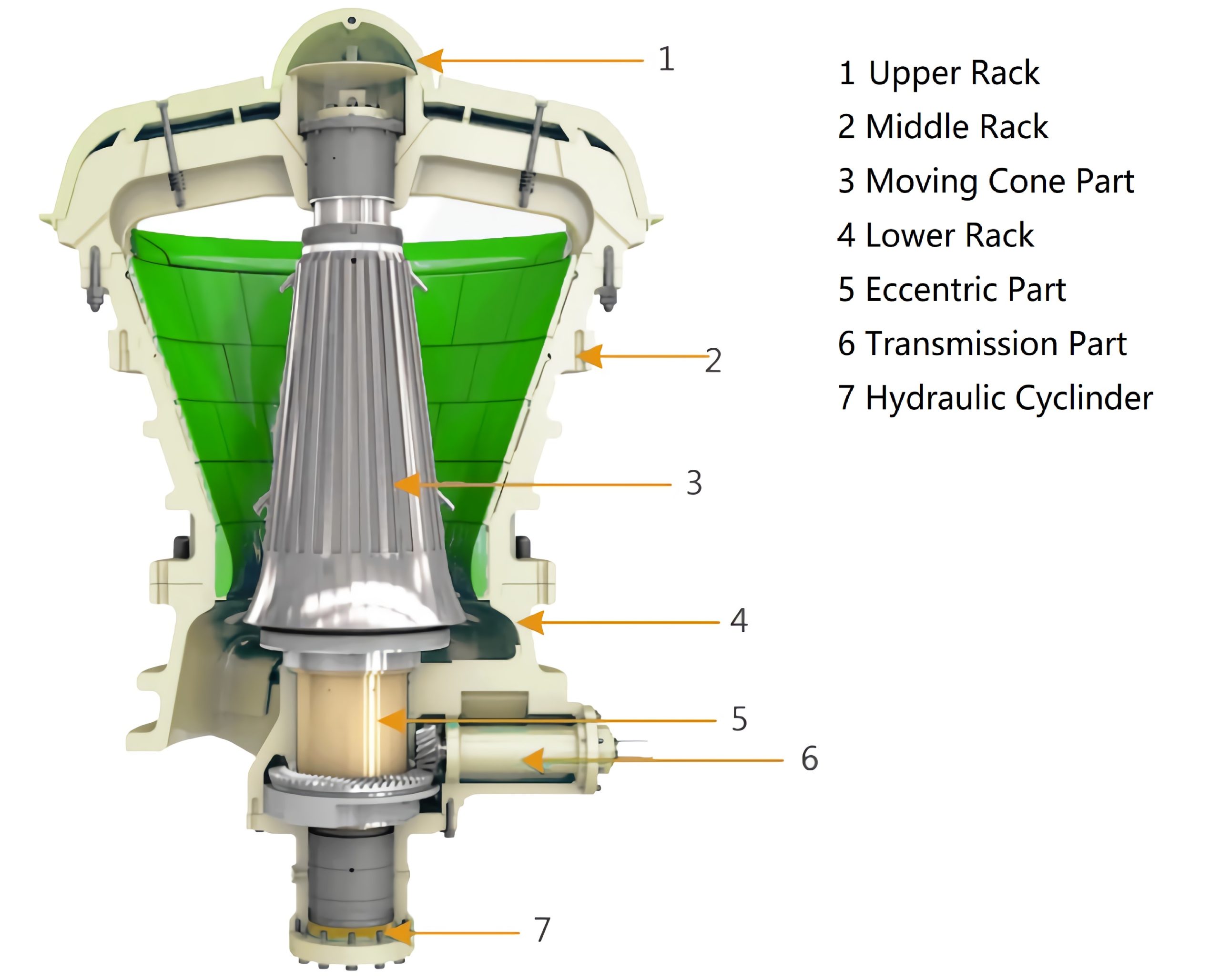

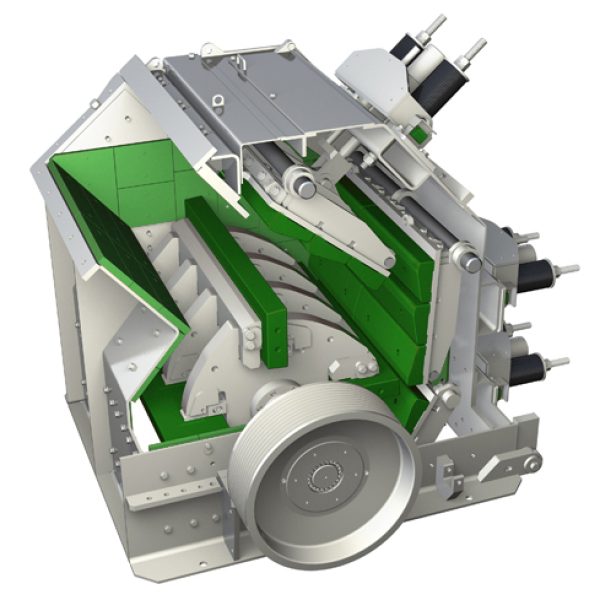

Gyratory Crusher Parts

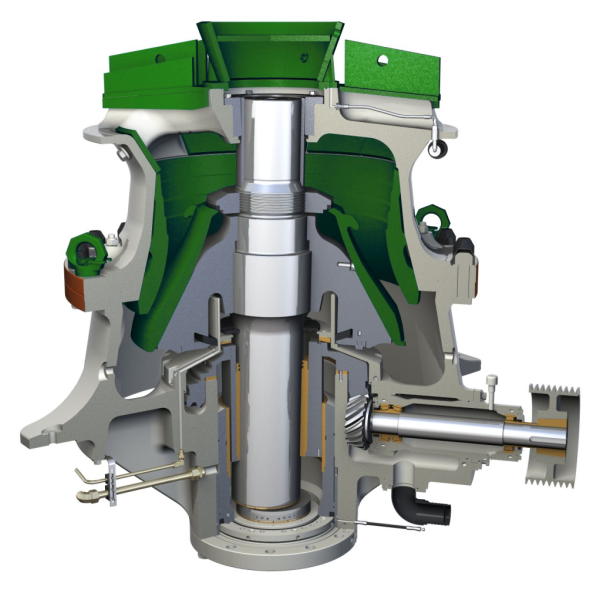

Gyratory crusher is a compressive style crusher for primary-stage applications. Its steep crushing chamber and long crushing surfaces provide exceptionally high capacity and long liner life. It consists of a concave surface and a conical head; both surfaces are typically lined with manganese steel. The top of the shaft attached to the crushing cone is supported centrally in the bushings, and the bottom of the shaft is positioned in an eccentric bushing.

The feed material is crushed between the fixed concave surface and a movable mantle. The bigger rock material is crushed against the mantle and the concave.Matec Solutions supply various alloys, designs and sectioned mantles to achieve the best cost per produced ton, depending on the application and the wear rate. Genuine replacement for Metso Superior Crusher parts.

Gyratory Crusher Parts Applications:

Mining, Quarry, Cement, for crushing hard and medium hard ore and rock, such as iron ore, copper ore, limestone, sandstone

Features:

1, Dimension accuracy and Compatibility is guaranteed;

2, Customized dimension and material service is available;

3, Reliable performance is assured by good quality;

4, Superior wear resistance property optimized for longer service life.

5, Brand Supported:

Metso: Superior 42-65, Superior 50-65, Superior 62-75.

Specifications:

Standard Material:

High Manganese Steel

| Material | C | Si | Mn | Cr | Mo | Ni | Cu | S | P |

| Mn14Cr2 | 1.0-1.3 | 0.3-0.6 | 11.0-14.0 | 1.7-2.5 | / | / | / | ≤0.03 | ≤0.05 |

| Mn18Cr2 | 1.1-1.4 | 0.3-0.6 | 17.0-20.0 | 1.7-2.5 | / | / | / | ≤0.03 | ≤0.05 |

| Mn22Cr2 | 1.1-1.4 | 0.3-0.6 | 20.0-24.0 | 1.7-2.5 | / | / | / | ≤0.03 | ≤0.05 |

Reviews

There are no reviews yet.