Description

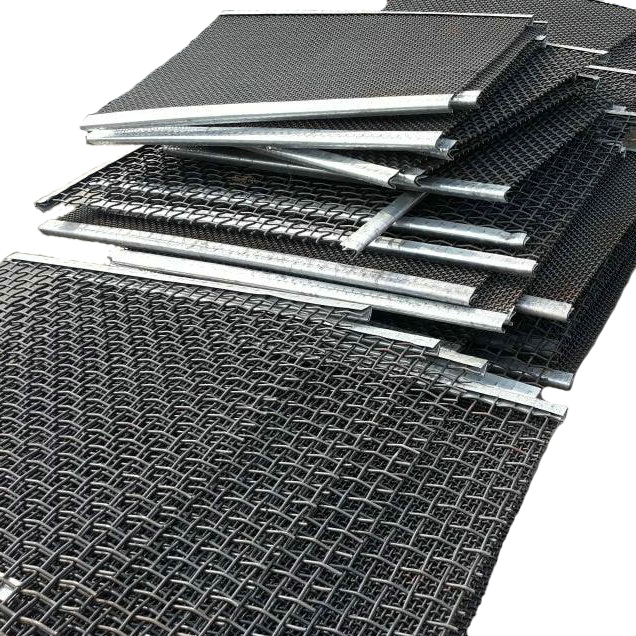

Manganese Steel Mesh

Matec Solutions produce Manganese steel mesh of high tensile, wear and abrasion resistant and long service life. Generally, Manganese steel vibrating screen is installed as the screen deck in the stone crushers, vibrating screens, and trommel screens.

When the screen mesh is used under strong impact and friction application, the surface will form strong work hardening due to plasticity, and the surface hardness can increase up to more than HRC60, and the mesh obtains higher wear resistance, while the wire interior still maintains higher plasticity and toughness. As the external surface wears out, the new surface will form a wear-resistant layer again, so the service life can reach 4-8 times of the ordinary screen.

Application:

Mining, Quarry, Aggregate

Features & Specifications:

High strength, Wear resistance, Corrosion resistance, Mesh uniform

Material: High tensile spring steel, manganese steel, High carbon and medium carbon steel wire, black wire, and stainless steel wire.

Wire diameter: 0.71–14 mm.

Opening size: 1–110 mm.

Surface treatment: Galvanized before weave and galvanized after weave, painted.

Hole type: Square mesh, rectangular mesh.

Hook Type: C or U hook for 30° – 180°

Weaving type: Double crimped, intermediate crimped, flat top crimped, lock crimped.

Edge preparation: Plain, bent, reinforced shroud, welded shroud, bolt shroud.

Reviews

There are no reviews yet.