Description

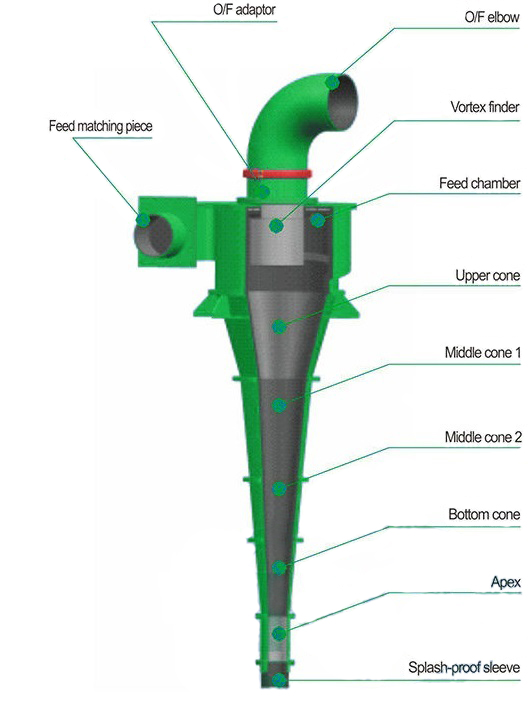

Rubber Cyclone Liners

Matec Solutions manufacture rubber CAVEX cyclone liners replacements, they are designed for heavy duty industrial applications, particularly where high wear necessitates the regular checking and replacement of internal wear liners. Typically, site experience will determine the frequency with which particular cyclone components will require replacement. For example, it is normal for the spigot liner to

wear out faster than the cone liners.

Each of the casing segments has a corresponding moulded elastomer liner, commonly natural rubber, which fits snugly into its casing housing. Liners can be easily inspected by unbolting and removing the casing segments. CAVEX cyclone liners do not require any adhesives or special tools for replacement.

All components are part numbered.

Name: Feed chamber/ Vortex Finder/Cone/Spigot-Apex

Applications:

As an universal separating and classifying equipment, widely used for mineral processing, desliming, thickening and also dewatering operations.

Features & Specifications:

Compatible with CAVEX Cyclone;

Dimension accuracy and Compatibility is guaranteed;

Superior abrasion resistance for a longer wear life.

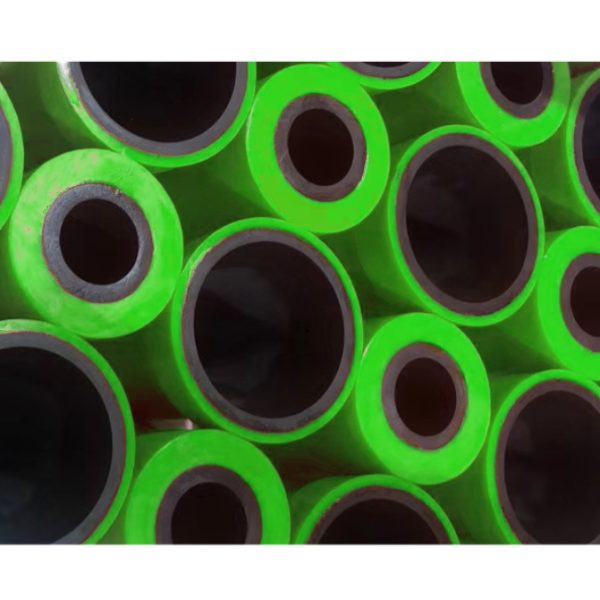

High wear resistant rubber

The rubber is with excellent flexibility and presents performance of good abrasion resistance, also acid and alkali resistance.

| physical characteristics sheet of high wear resistant rubber | |||||

| Shore Hardness | Compression Strength(MPa) | Tear Strength(n/mm) | Elongation(%) | Resilience (%) | Permanent Deformation(%) |

| 45 | ≥25 | 44 | ≥800 | ≥80 | ≤15 |

Reviews

There are no reviews yet.